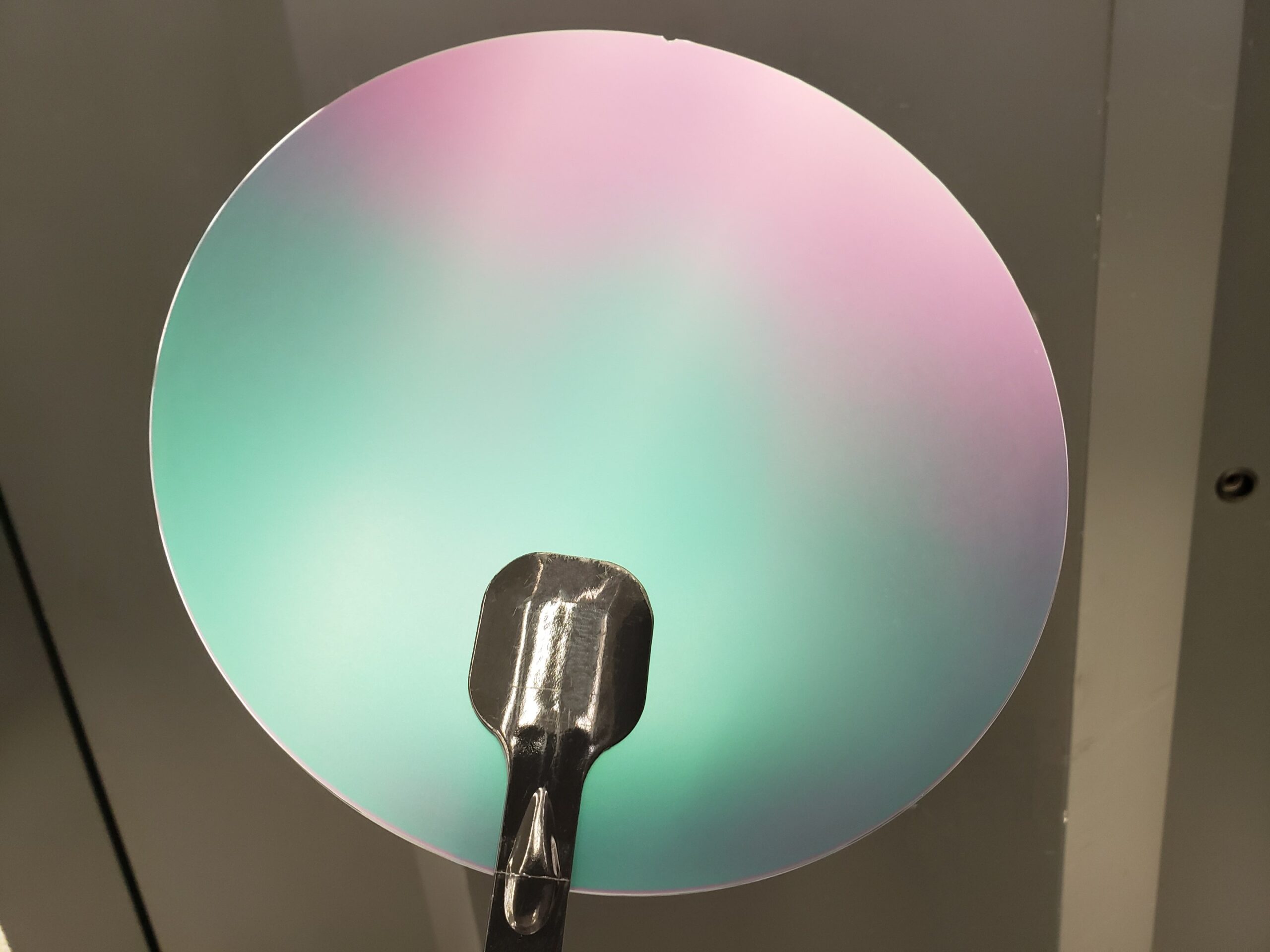

To support the epitaxial deposition process, GlobiTech operates a 125,000 square foot facility. Currently in production are two 8,000 square foot Class-1 cleanrooms (Fab 1/Fab2) for 100mm through 200mm epi wafer production. Both cleanrooms utilize ballroom equipment configuration for optimal equipment placement and product flow. Waffle deck flooring is incorporated to provide uniform airflow throughout the room.